During our activities, we strictly focus on three major dynamics;

We are providing

We are providing high-quality cost effective B2B contract manufacturing steel fabrication service for our Global Partners with Schedule-driven approach. With our assembly line feeding experience, we have been serving our partners in Construction Machine, Agricultural Machine, Special Vehicles, Defense etc.

When your design is ready for production we have all main processes internally available to complete your products and deliver in a timely manner like;

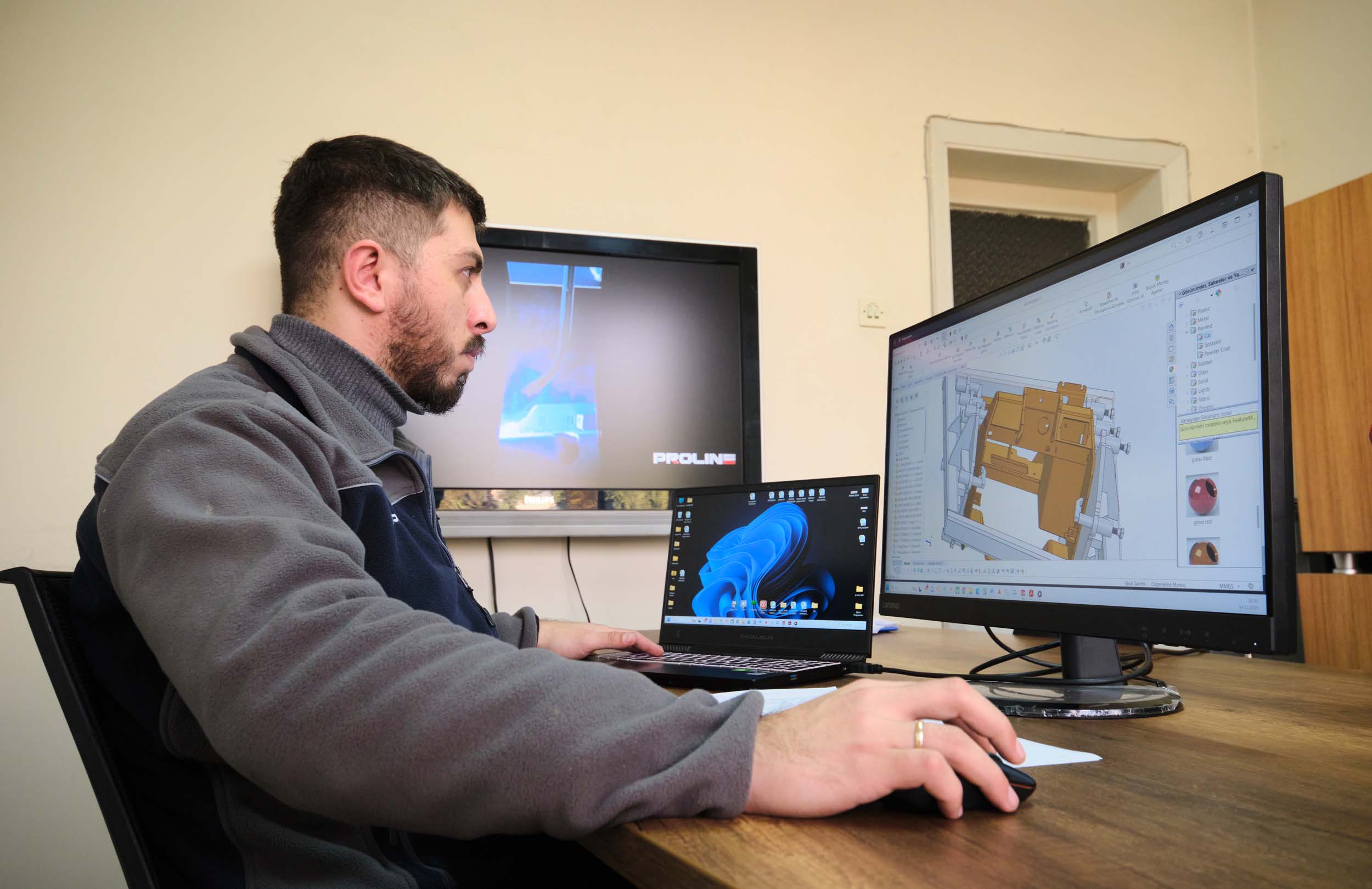

Design & Engineering

Quality in all steps

Prototyping and pre-serial

Cutting and Forming

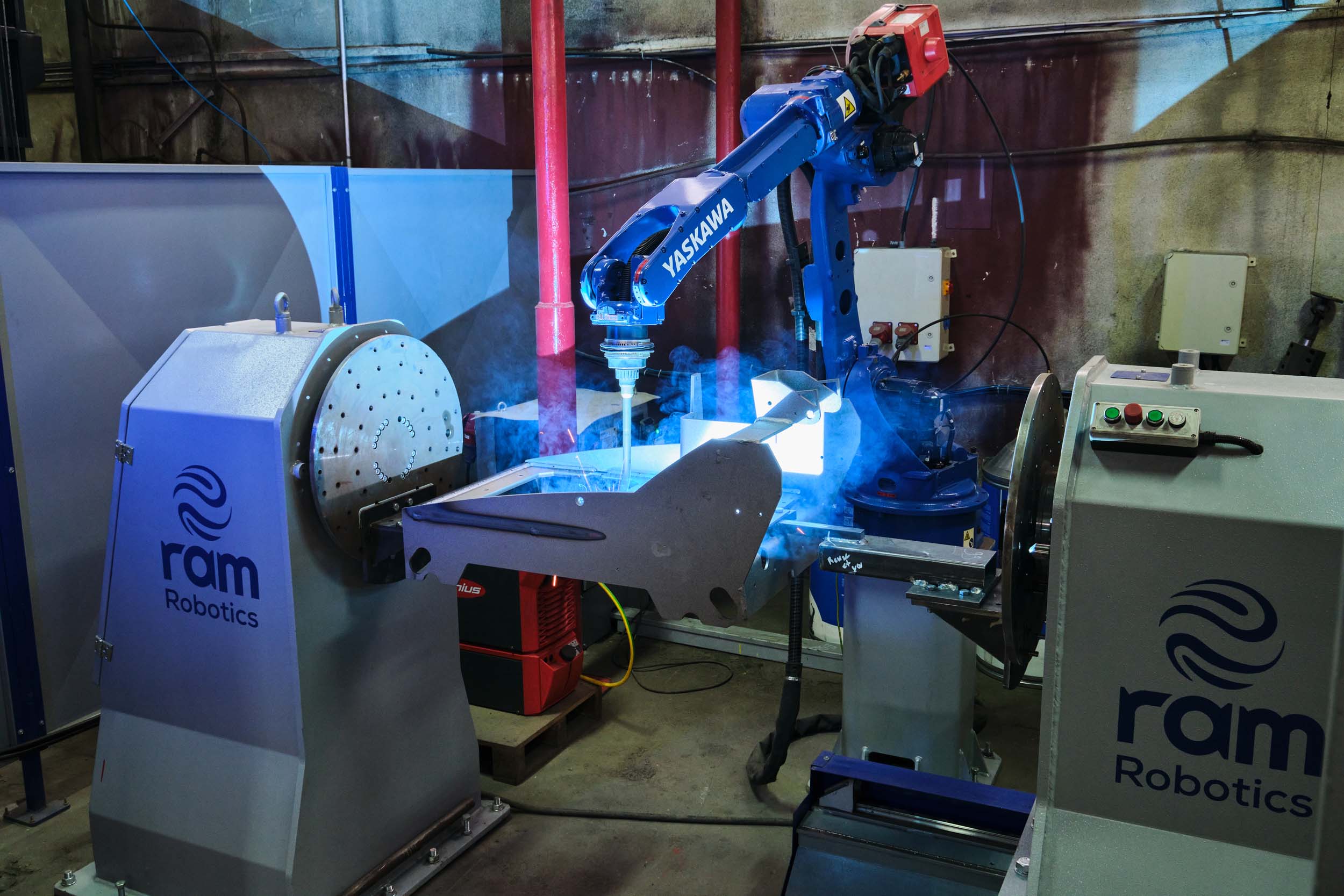

Manual and Robotic Welding

CNC Machining

Surface Treatment

Packing and Dispatching.

If you are in design phase, we can to involve in your project as a Co-Designer in order to cost reduction manner for all metal parts.